RFID Case Study: Enhancing wine logistics and ensuring traceability

Mosnel, a prestigious winery in Italy’s Franciacorta region, has been producing high-quality wines since 1836. To maintain its reputation and respond to the challenges of modern wine logistics, Mosnel partnered with SAIT to implement Wineability to face the challenges. This approach helped Mosnel address issues in product traceability, market control and regulatory compliance.

Challenge

As the global wine market became more competitive, Mosnel faced several issues. Unauthorized reselling of their wines and violations in distribution channels risked damaging their brand’s reputation. At the same time, warehouse operations were becoming less efficient. In 2023, new European regulations also required detailed information on nutritional values, ingredients and disposal instructions to be displayed on wine labels.

Mosnel needed a solution that could give them full control over the distribution of their wines, streamline warehouse processes and ensure compliance with these new rules.

Solution

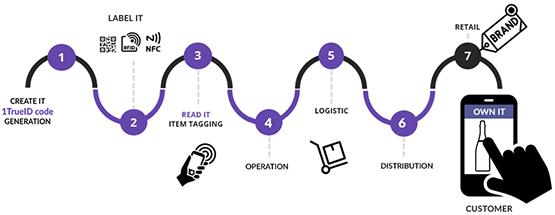

To meet these challenges, Mosnel implemented Wineability, a custom software developed by SAIT, combined with RFID technology and 1TRUEID QR codes. RFID tags were placed discreetly on each wine bottle and scanned at different stages during packing, shipping, and storage, allowing Mosnel to track each bottle’s movement in real-time, ensuring complete control over distribution channels.

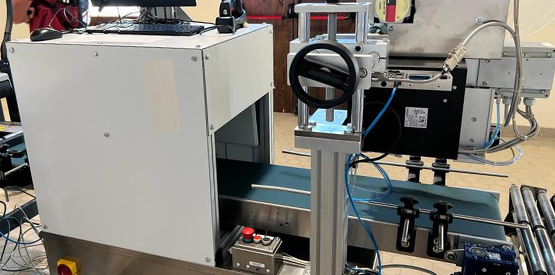

In their warehouse, Mosnel used Kathrein RRU 4500 Reader Units and WRA 7070 Antennas on a tunnel system to scan bottles during the packaging process, enabling the team to know exactly which bottle goes in which box. Thanks to this RFID portal, Mosnel tracks products with precision, knowing the exact position of each bottle in the warehouse. This automated tracking system helps locate and organize bottles quickly, reducing errors in picking and shipping and improving overall efficiency.

By simply scanning the QR code on each bottle, both the winery and its customers can verify the wine’s authenticity and trace its journey from vineyard to consumer. The solution also identifies unauthorized reselling, allowing Mosnel to take action and protect their brand. Additionally, the Wineability platform simplifies compliance with new regulations by communicating the information required by the law.

Results:

Mosnel achieved impressive results with this system:

- 100% distribution control: Mosnel now has full visibility of their distribution channels, allowing them to identify and replace non-compliant distributors and reduce unauthorized reselling.

- 30% more efficient warehouse operations: The automated system reduced errors in picking and deliveries to zero and made warehouse management faster and more accurate.

- Improved customer experience: Consumers can now easily access detailed product information and traceability data by scanning the QR code on each bottle. Through the Wineability app, customers also have access to exclusive content and can join the Wine Club, creating a more personal connection with the brand.

- Regulatory compliance: With Wineability, Mosnel easily met the new European regulations, automatically providing the necessary information on each bottle.

Conclusion

By adopting RFID technology and the Wineability software developed by SAIT, Mosnel has successfully solved the challenges of product traceability, market control and regulatory compliance. This innovation has protected their brand and improved both their operations and customer relationships, ensuring Mosnel’s position as a leader in the wine industry for years to come.

Used Cisper products: